This comprehensive road roller buyer’s guide covers all major types of rollers. It explores the advantages of buying new versus used equipment, emphasizing reliability and cost-effectiveness. It also explains key performance parameters such as operating weight, compaction width, and maneuverability to help you choose a roller. It emphasizes the importance of a thorough inspection, verifying documentation, and selecting a certified dealer for after-sales support. It also provides insights into maintenance considerations and key factors to consider during the purchase process. Overall, this guide is designed to help readers make informed decisions when purchasing a road roller.

Table of Contents

I.Introduction to Road Roller

1.1 What is a road roller?

Road rollers are widely used in various industries. In highways, railways, airports, water conservancy projects, and construction projects, they are primarily used to compact roadbeds, pavements, levees, cofferdams, and building foundations. Small rollers are particularly suitable for compacting narrow spaces.

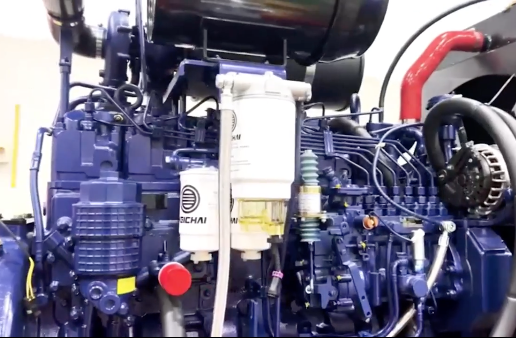

Structurally, a roller typically consists of a power unit, transmission system, working device, and steering and braking systems. The power unit typically uses a diesel engine as its power source, providing powerful power to the entire machine. The transmission system is responsible for transmitting the engine’s power to the various working components, enabling the roller’s travel, vibration, and other functions. The working device is the part of the roller that directly acts on the material being compacted. When the motor inside the wheel rotates, it drives the vibrating shaft along with it, generating vibrations that hammer the ground, making the road surface more compact.

1.2 Benefits of buy road roller

Purchasing a road roller can significantly improve project quality, ensuring the desired compaction level. It can also significantly improve construction efficiency, shorten construction schedules, and reduce labor costs. In the long run, owning equipment, rather than renting it, offers greater control over costs and schedules, resulting in long-term economic benefits for ongoing project owners.

II. Road Roller Types

2.1 Single drum road roller

Single drum road roller are primarily used for compacting foundation layers such as soil, gravel, and rock fill. They feature a large steel drum at the front that uses high-frequency vibrations for deep compaction, and a rubber-driven rear drum. This is the most common type of roller used in earthmoving projects.

-

Single Drum Rollers

16Ton Single Drum Vibration Road Roller Machine WS160D EU Stage V Emission

Read more -

-

-

2.2 Double drum vibratory roller

A tandem vibratory roller features front and rear steel drums with a vibrating function. It is primarily used for compacting asphalt pavement, creating a smoother, denser surface. This type of roller is commonly used in the final stages of asphalt pavement construction. It is suitable for compacting large asphalt pavements, offering high efficiency and speed. However, a limitation of tandem rollers is their low traction, making them unsuitable for complex terrain.

2.3 Pneumatic Tire Roller

A pneumatic tire roller , sometimes called a pneumatic tire roller, is a large, riding roller with several rows of rubber tires at the front or rear. The rubber tires provide 80% coverage and uniform pressure across the entire tire width.

They are commonly used on sidewalks to help with leveling and polishing projects, but are also suitable for cold-laid asphalt or cold-mix pavement and loose soil layers.

-

-

-

Pneumatic Tire Rollers

26 Ton Pneumatic Asphalt Roller WP267H with Tire4 Emission Standard

Read more -

Pneumatic Tire Rollers

30 Ton Pneumatic Rubber Tired Roller WP307H with Tire4 Emission Standard

Read more

2.4 Trench rollers and plate compactors

Trench rollers and plate compactors are small compaction machines designed to fit into tight spaces where larger rollers can’t. They’re commonly used for trench backfilling, curbside compaction, and small road repairs, making them an effective complement to larger projects.

III. New vs. Used Road Roller Decisions

To more intuitively illustrate the decision-making basis, we conducted a lifecycle cost analysis using a five-year-old, 22 ton used big road roller and a new, fully hydraulic road roller of the same tonnage as examples :

| Cost Item | Used Road Roller (5 years old) | New Fully Hydraulic Road Roller |

| 1. Initial Road Roller Price | Surface 22 Ton Big Road Roller Price: ~$24,000 – $30,500 | Higher Road Roller Price, but transparent with no hidden fees. |

| Actual Cost: Must account for broker fees (~$2,800), market premium (~$4,200), etc. Final cost can reach $30,500 – $38,200. | ||

| 2. Maintenance & Repair | High risk, high potential cost. Unless you are an expert, easy to be deceived. May require immediate investment of ~$1,400 to $7,000 or more to replace critical components like the engine or hydraulic pumps, with no warranty. | Low to zero cost. Covered by nationwide warranty. Maintenance costs are predictable, and repair costs are nearly $0 during the warranty period. |

| 3. Fuel Cost | Low efficiency of mechanical transmission, high impact during direction changes, leading to high fuel consumption. Based on 8 hours/day and a fuel Road Roller Price of ~$0.76/L, annual extra fuel cost is ~$11,100 compared to a new machine. | Fully hydraulic transmission ensures smooth load changes and low fuel consumption. Significant long-term fuel savings. |

| 4. Service Life & Earnings | The prime service life is ~10 years. After purchase, only about 5 effective revenue-generating years remain. With a monthly rental fee of ~$2,100, 5-year earnings are ~$126,000. | Has a full 10-year or longer prime revenue-generating life. With the same rental fee, 10-year earnings can reach $252,000, double that of the used machine. |

| 5. Total Cost of Ownership | Initial Road Roller Price: $30.5K-$38.2K + Potential Repairs: $1.4K-$7K + 5-Year Extra Fuel: ~$55.5K = High Total Expenditure. Total earnings ~$126K. Net profit is severely eroded by high hidden costs. | Although the initial Road Roller Price is higher, there are no hidden repair costs, lower fuel costs, a longer revenue cycle, and higher total earnings. Net profit far exceeds that of a used machine. |

Based on the above data, it can be seen that buying a used roller that has been used for 5 years is cheaper than a new one on the surface. However, if the inflated purchase cost, high potential repair and maintenance costs, astonishing fuel consumption difference and halved revenue-generating years are taken into account, the total cost of ownership may be far higher than expected, and the actual net profit is far lower than that of a new machine.

Therefore, if you’re seeking long-term, stable, high returns while mitigating uncontrollable risks, a new machine is far more valuable than a used one . It’s more than just a production tool; it’s an asset that delivers guaranteed returns. Unless you’re an expert who can accurately identify the condition of your equipment and purchase it at a rock-bottom price, for most users, investing in a new machine is the wiser and more economical choice.

IV. Key features to consider before purchasing

4.1 Road Roller Working weight and exciting force

Operating weight and excitation force are core performance parameters of a roller. Together, they determine the equipment’s compaction capacity and impact depth. Purchasers need to consider these parameters based on the primary material being compacted (e.g., earth or asphalt) and the thickness of the compacted layer.

4.2 Compaction width and efficiency

The width of the drum directly determines the coverage area of a single rolling operation, which in turn affects overall work efficiency. While ensuring adequate accessibility on the construction site, choosing a model with wider drums generally results in higher compaction efficiency.

4.3 Drive system and mobility

The machine’s drive system and maneuverability are crucial. Buyers should check whether the steering system is articulated or wheel-steering, and pay attention to its gradeability and minimum turning radius. These parameters directly determine the machine’s agility on narrow or complex construction sites.

4.4 Technical additional features

Modern rollers may be equipped with a variety of additional technical features, but intelligent compaction systems are particularly crucial. These systems monitor the degree of compaction in real time, guiding the operator to avoid over- or under-compaction, thus conserving material while ensuring quality. This makes them a worthwhile investment for high-standard projects.

V. Brand and dealer selection

5.1 Overview of top road roller brands

The mainstream brands in the market can be divided into two camps: international and domestic. road roller manufacturer such as Dynapac, Wirtgen, Bomag, etc. are known for their leading technology and durability, but the price and maintenance costs are relatively high. China road roller manufacturer such as XCMG, Sany, Liugong, etc. have extremely high cost performance, extensive after-sales service network, and rapid supply of spare parts.

Qhmach roller manufacturer is a cost-effective choice. We focus on the upgrade and research and development of rollers. After several years of development , we have formed four series, including fully hydraulic single steel wheel, fully hydraulic double steel wheel, fully hydraulic rubber wheel, garbage compactor, etc., more than 60 varieties of products, with tonnage ranging from 3 tons to 36 tons.

5.2 The Importance of Certified Dealers

It’s crucial to purchase equipment from a brand-authorized, certified dealer. This ensures the equipment comes from a legitimate source and is covered by an officially recognized warranty and after-sales service. Authorized dealers often also provide professional operating training and ongoing technical support.

VI. Market Price Research

6.1 Understand the Road Roller Manufacturer Suggested Retail Price and Dealer Price

The road roller manufacturer suggested retail price (MSRP) is an important reference, but the actual transaction price is often negotiable. The most direct way is to contact multiple dealers to obtain written quotes and compare them. Compared to conventional mechanical rollers, Qhmach fully hydraulic rollers offer significant improvements in gradeability, road quality, driving safety, and operating efficiency. More importantly, while focusing on quality, fully hydraulic rollers maintain pricing consistent with conventional mechanical rollers, ensuring customers enjoy hydraulic products at mechanical prices.

6.2 Where can I find reliable price comparisons ?

For reliable price comparisons, visit the official websites of major brands and dealers. Professional construction machinery portals, offer quote centers and a wealth of equipment information.

You can also find suitable roller products or suppliers on equipment listing sites like MachineryTrader, Ritchie Specs, or Iron Planet, construction equipment forums, and Reddit.

VII. Equipment inspection before purchase

7.1 Engine and hydraulic system inspection

Engine inspections include ensuring smooth startup, unusual operating noises, and the emission of black or blue smoke. The condition of the engine oil and coolant should also be checked. For the hydraulic system, all cylinders, valve blocks, and piping should be inspected for leaks. All functions should be operated to ensure smooth and powerful movement.

7.2 Wear condition of steel wheels and tires

When inspecting steel wheels, focus on whether the surface wear is even and whether there are any serious scratches, pits, or weld cracks, as excessive wear will directly affect the compaction effect. For tire rollers, it is necessary to check the tread wear and tire pressure, and observe for cuts or bulges.

7.3 Test drive and vibration test

A personal test drive is essential. Check that the driving, steering, and braking systems are functioning properly. It’s especially important to activate the vibration function, feel the smoothness and strength of the vibrations at different frequencies, and listen carefully for any unusual noises.

VIII. Things you must pay attention to when buying a road roller

8.1 Hidden structural damage and repair

For used equipment, be wary of hidden structural damage or irregular repairs. For example, irregular weld marks on a wheel or repaired cracks in a frame rail could be signs of a major problem.

8.2 Missing key documentation

Missing key documentation is a huge risk signal. If the equipment lacks a factory certificate, original purchase invoice, or a continuous and complete maintenance record, its history is unclear, and its value and reliability are questionable.

8.3 Unverified ownership

Always verify the device’s clear and legal origin. Avoid purchasing equipment without clear proof of ownership, as it may be collateral or involved in a debt dispute.

IX. Maintenance and warranty protection

9.1 Understand warranty coverage

Before signing a contract, you must carefully read and understand the warranty terms. Be clear about the warranty duration and scope (whether it covers the entire device or just core components), as well as any exceptions to the warranty.

9.2 After-sales service and parts supply

It is crucial to choose a brand and dealer with a comprehensive after-sales service network and timely parts supply. This can minimize equipment downtime caused by waiting for repairs and parts, ensuring the smooth progress of the project.

9.3 Regular maintenance plan

Following the road roller manufacturer recommended regular maintenance schedule is key to ensuring equipment life and reliability. This includes changing engine oil, hydraulic oil, filters, etc. on time and strictly following the maintenance manual.

X. Final Recommendations

Purchasing a road roller is a significant investment, so avoid rushing into it. You need to clearly define your project requirements to select the right type of roller. Then, consider weighing new versus used options and investing time in thorough market research. If you have any questions or needs regarding road rollers, please contact us. With over 20 years of experience in the road roller industry, Qhmach is eager to assist you!