In island road construction, roller machine for road construction is crucial for scattered sites and tight spaces. This case study shows how WALMACH’s road roller combination solution meets complex needs in Indonesian resorts through customized setups.

I. Country and Project Background

Country: Indonesia

Project Background: Construction of internal roads and small parking lots for multiple island tourism resorts. The projects are geographically dispersed, and construction sites are often constrained.

II. Client Background

The client is a well-established Indonesian local tourism real estate development company founded in 2007. In recent years, the group has consistently focused on the development and operation of high-end island tourism resorts and supporting communities. Its business has expanded from the core area of Bali to ecological islands such as Lombok, successfully creating more than ten award-winning benchmark resort projects.

III. Client Requirements

- Versatility and Cost-Effectiveness: Needed a comprehensive suite of road roller equipment to reduce the costs associated with transporting machinery between multiple islands.

- Construction Capability in Confined Areas: Required compact equipment to handle complex areas within the resorts, such as landscape paths and spaces around villas.

- Environmentally Friendly: Equipment needed to have low noise and low emissions to avoid impacting the surrounding ecological environment and tourist experience.

IV. WALMACH Road Roller Solution

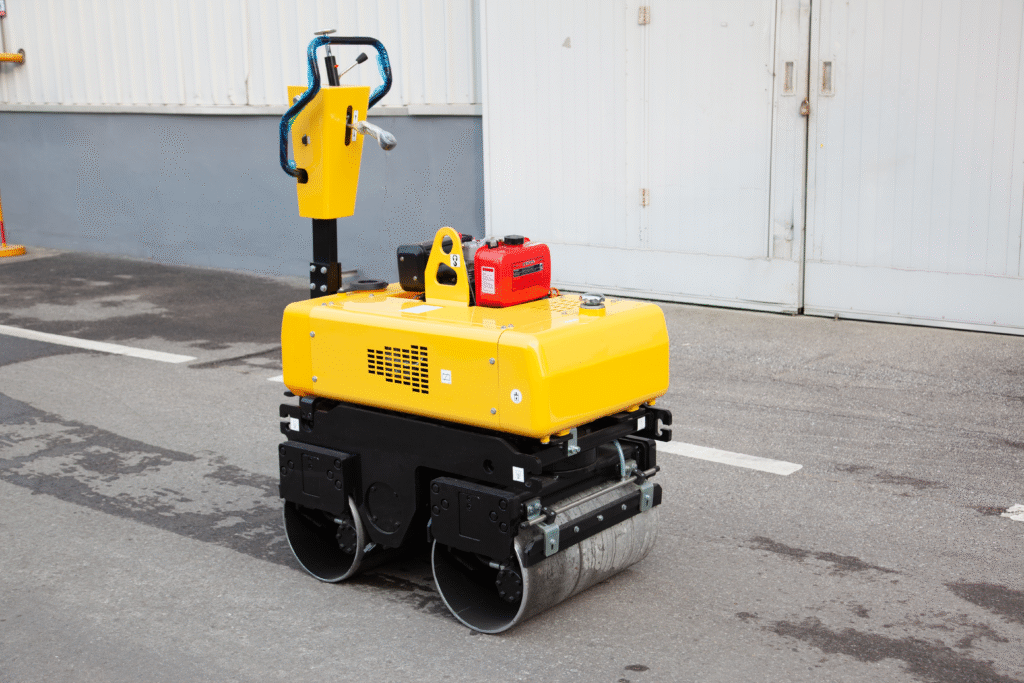

To address the challenges of Indonesia’s island projects, WALMACH provided a tailored equipment package comprising the WS176D (17-ton) single drum road roller, the WP206 (20-ton) pneumatic tyre roller, and the WD008 (0.8-ton) walk behind vibratory roller:

Combined Process: The “single drum road roller + pneumatic road roller” sequence covers all compaction stages, from earthwork to asphalt surfacing.

Operational Flexibility: The fully hydraulic rollers allow for easy relocation, while the WD008 walk behind vibratory roller easily accesses confined spaces.

Environmental Adaptation: Special anti-corrosion treatment was applied to withstand the marine climate and enhance durability.

V. Overview of Cooperation

The client contacted us after an online search for “compact roller solutions.” Following in-depth discussions about their multi-island operations, space constraints, and environmental priorities, WALMACH proposed the customized WS176D, WP206, and WD008 package. This solution stood out for its cost efficiency through versatility, excellent adaptability to limited spaces, and purpose-built corrosion resistance, ultimately winning the project based on its strong fit and overall value.

VI. Client Feedback

“WALMACH’s equipment package increased compaction efficiency by approximately 40% while flexibly meeting construction needs across multiple islands, delivering outstanding ease of maintenance.”