Table of Contents

I. Introduce

The harsh winter conditions of cold, snow, and dampness pose a severe challenge to all construction machinery, including road construction. Low temperatures exacerbate the brittleness of metal components, reduce the fluidity of various oils, leading to starting difficulties, performance degradation, and even serious malfunctions. Winter is a critical period for the use and maintenance of road roller. Proper maintenance measures can ensure the equipment operates normally in low-temperature environments and extend its service life. As a road roller manufacturer with over 20 years of experience, Qhmach provides you with a complete guide to winter maintenance for road rollers, helping your road roller equipment successfully navigate the winter and operate efficiently and safely even in cold weather.

II. Why is winter maintenance crucial for road construction roller?

As heavy compaction equipment, road rollers are particularly vulnerable at low temperatures due to their hydraulic systems, vibration systems, and engines. Improper maintenance can lead to:

- Starting failure: Reduced battery performance, thickened engine oil, making it difficult to start.

- Increased component wear: Ineffective lubrication by the oil leads to dry friction inside the engine and hydraulic pump.

- Performance degradation: Slow hydraulic action and unstable vibration frequency affect compaction quality.

- Increased costs: Significant losses due to maintenance expenses and downtime.

Therefore, proactive winter maintenance is not an option, but a necessity.

III. Preparations before winter arrives

A thorough inspection and maintenance before temperatures plummet is the first step to success.

First, conduct a thorough visual and functional inspection of the entire machine . If there is dirt on the surface of the roller, be sure to clean it thoroughly and keep the machine clean . Second , confirm that the engine oil, hydraulic oil, and coolant levels are all within the standard range. At the same time, low temperatures can cause rubber products to harden and become brittle , so carefully check all hoses for cracks and bulges, and belts for signs of aging and looseness, and replace them promptly.

IV. a road roller Fuel system maintenance

Use winter-grade diesel fuel: The engine oil of the road roller needs to be changed regularly , especially in low-temperature environments. It is essential to select the appropriate grade of diesel fuel based on the local lowest temperature . If the lowest temperature is above -10℃, use -10 grade diesel fuel; if it is below -10℃, use a higher grade diesel fuel to avoid poor fuel supply to the engine due to low temperatures, which could prevent the machine from starting and operating normally. This also prevents the diesel fuel from waxing and clogging the filter and fuel lines.

Keep the fuel tank full: Fill the fuel tank at the end of each workday. This reduces moisture buildup on the tank’s inner walls caused by temperature fluctuations, preventing the fuel system from freezing.

V. Battery maintenance

Prevent water leakage in cold weather: Low temperatures can cause a rapid drop in battery power. Ensure battery terminals are clean, secure, and coated with a special grease to prevent corrosion. Disconnect the battery if the equipment will be idle for an extended period.

Store spare batteries: For road rollers operating in extremely cold regions, consider storing spare batteries in a warm environment for easy replacement.

VI. Hydraulic System Protection

Choosing the right hydraulic oil is crucial for winter hydraulic system maintenance. Please replace it with a low-pour-point, high-flow-rate winter hydraulic oil as recommended by the manufacturer to reduce starting resistance and ensure lubrication. Because of the low winter temperatures, the viscosity of the hydraulic oil increases, leading to increased negative pressure in the hydraulic pump and insufficient oil supply. This can affect the accuracy and sensitivity of the actuators, so it’s essential to use the specified type of hydraulic oil to ensure smooth system startup and protect the hydraulic pump and motor .

Check for leaks: Low temperatures can cause seals to shrink, leading to leaks. Before starting the machine each day, check hydraulic lines and joints for signs of leakage.

VII. Proper lubrication

Choose a winter grease: Discontinue the use of summer-grade lithium-based grease and replace it with a lower viscosity, low-temperature-resistant winter grease (usually marked with 0 or 00).

Lubricate critical components: Focus on lubricating vibration bearings, steering bearings, hinge points, all pins, and bushings. Lubricate before each workday to ensure the grease fully covers the components and remove any moisture that may have gotten in.

VIII. vibrating drum roller Steel wheel and tire maintenance

The steel wheel of the vibrating drum roller is its core working device and requires special care in winter.

Check for wear and clean: Regularly check the vibro road roller steel wheel surface for excessive wear or asphalt residue. After work, be sure to promptly clean any ice, snow, mud, and residual material adhering to the steel wheel to prevent freezing and affecting balance and compaction.

Apply anti-sticking agent: When compacting asphalt mixtures, use a winter-formulated anti-sticking agent to prevent the materials from sticking together excessively.

Road roller tire inspection : In winter, tires become harder and more brittle, reducing their coefficient of friction and making them more prone to leaks and punctures. Therefore, tires should be regularly inspected for obvious damage, scratches, and wear, and excessively worn tires should be replaced promptly. Additionally, debris should be regularly removed from the tire treads, and tires that have been patched multiple times should be avoided.

IX. Engine maintenance and preheating

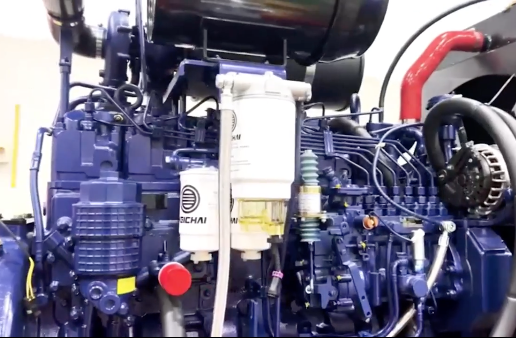

For engines, the high viscosity of engine oil during cold starts can cause insufficient lubrication in a short period of time, preventing it from reaching all lubrication points. If the engine runs at high speed at this time, it can lead to increased wear on the crankshaft, camshaft, and rocker arm shaft, or even serious accidents such as cylinder scoring and bearing failure.

Use an engine block heater: This is the most effective cold start aid. When the equipment is not in use (especially at night), plug in the block heater to maintain the engine block and oil temperature, significantly reducing the starting load.

Preheat the engine: After starting, do not immediately engage high-speed operation. Let the engine run at low idle speed for 10-15 minutes to allow the engine oil temperature to gradually rise and circulate to all parts requiring lubrication. Similarly, preheat the hydraulic system in the same way. If the temperature is too low, the hydraulic oil viscosity will be high, making oil suction difficult, resulting in insufficient oil pumping and affecting the strength and sensitivity of actuators. Applying load at this time could also cause serious accidents due to excessive negative pressure .

X. Preventing snow and ice accumulation

Proper storage of the road roller: After each day’s work, park the equipment on a flat, firm surface.

Covering key components: clearing road roller machine snow and ice from the cab roof, engine hood, and steel wheels to prevent water from seeping in after melting, or ice from falling and causing danger.

XI. Storage and shielding solutions

Disassembly and storage: If the vehicle is parked outdoors or in a cold storage for several weeks without use, the battery should be removed and stored in a warmer room to prevent it from freezing and being damaged.

Use a heated garage: Ideally, equipment should be stored in an indoor garage to avoid direct exposure to wind and snow.

Covering the machine: If it can only be stored outdoors, be sure to use a rainproof tarpaulin to cover the entire machine, especially the engine, hydraulic pump and cab.

Perform a rust prevention test once a month : Start the engine and run it once. In cold weather, place the key in the preheating position and preheat it 3-5 times. At the same time, you can also run the air conditioning system once to first warm up the cab, then let the refrigerant circulate through the air conditioning system once, and at the same time check whether the electrical system is normal.

XI. Road Roller Winter routine maintenance and inspection

Morning and evening inspections: Develop the habit of inspecting the machine before starting work and after finishing work.

Monitor fluid levels: Check the oil level daily to ensure there are no leaks.

Check the hydraulic oil level to ensure it is normal. Use low-freezing , anti-wear hydraulic oil (No. 46). Also check the antifreeze level to ensure it is normal. The factory-set antifreeze ratio is 50%, and it can withstand temperatures as low as -40°C. Observe for any unexplained increases or decreases (which may indicate the introduction of moisture or a leak).

XII. Safety Precautions

To prevent the hydraulic system from freezing: Ensure the hydraulic system is properly sealed to prevent moisture from entering. In very cold weather, check that the hydraulic oil tank breather valve is clear.

Preventing operator fatigue: Winter operating environments are harsh. Ensure that the cab sealing and heating systems are functioning properly to provide operators with a safe and comfortable working environment and avoid operational errors caused by the cold.

XIII. Avoid common mistakes

- Error: Using summer-grade diesel and lubricating oil.

Correct practice: Always switch to winter-grade products based on the ambient temperature. - Error: Running at high speed or under load immediately after startup.

Correct practice: Strictly follow the preheating procedure. - Error: Neglecting to remove ice and snow from the steel wheels and chassis.

Correct practice: Thoroughly clean before the end of each workday to prevent freezing. - Incorrect: Leaving a low-charge battery overnight in low temperatures.

Correct practice: Charge it promptly or remove and store it.

XIV. Frequently Asked Questions

Q1: At what temperature below zero can a road roller stop working?

A: There’s no absolute standard; it mainly depends on the equipment’s configuration (such as whether it uses winter-grade fluid or has a preheating device) and maintenance condition. A properly maintained and modified road roller (such as with the addition of a heater) can operate even in environments as low as -30°C.

Q2: What if there’s no cylinder block heater?

A: You can use a portable fuel heater or hot air blower to preheat the engine compartment externally, but this is only a temporary solution. In the long run, installing a cylinder block heater is the best option.

Q3: How often should engine oil and hydraulic oil be changed in winter?

A: It is recommended to follow the manufacturer’s maintenance schedule. However, under harsh operating conditions, the oil change interval can be shortened appropriately. It is best to perform an oil quality test before winter and again after winter ends, and decide whether to change the oil based on the test results.

XV. Conclusion

Providing thorough winter maintenance for your road roller is a highly rewarding investment. By following the steps in this guide—from pre-winter preparation, oil selection, and proper preheating to routine cleaning and inspections—you will be able to minimize downtime caused by cold weather, protect your valuable equipment, and ensure projects run smoothly throughout the winter.